Microsphere-1250 is a new type of ultrafine pozzolanic powder material. It is a powder product with continuous particle size distribution, ultra-fine particle size and perfect positive spherical shape, which is produced by procedures such as separation, surface modification, density improvement, etc.

Microsphere-1250 is a global shape particle which almost doesn’t contain porous substance and the particle size is very fine which bring excellent filling and ball lubrication effect for concrete, and its physical water-reducing effect is remarkable. Under the conditions of the same slump, the water demand of concrete significantly reduces; besides, the flowing ability increases, and the water-reducing rate is about 15%.

Microsphere-1250 has a continuous and uniform particle size distribution between 0.1μm to 5μm, which makes the concrete gradation optimized excellent at the micro level. Therefore, the Concrete becomes much denser, the strength becomes higher, the impermeability and corrosion resistance are greatly improved as well. Microsphere-1250 is an optimization agent for concrete gradation.

Microsphere-1250, as a kind of aluminosilicate material with ultra fine particle, almost doesn’t react with the alkaline substances of concrete in the early stage of hydration reaction, although the average particle size of Microsphere-1250 is only 1.5μm. The strength of concrete is mainly improved by beads filling effect. Therefore, compared with other types of high specific surface area micro-filler (silica fume, etc), the concrete hydration heat is low and dry shrinkage is small in the early stage of hydration reaction. As the hydration reaction proceeds, the dense surface of Microsphere-1250 begin to be destroyed, the concrete becomes more denser, the strength becomes more higher.

Others:

Excellent rheology and workability; Excellent thixotropy; With features of reducing viscosity and the shear stress; The excellent performance of molding greatly reduce the commercial concrete slump loss in the long road transportation.

Higher activity coefficient, the activity coefficient of 28 days is 105% -110%, 56 days up to115% -120% (addition levels are 6% -24%).

Physical characteristics (approximate)

LOI 2 % (EN 196, part 2)

Particle shape spherical

Specific density 2.53 g/cm³ (EN 196, part 6)

Apparent density loose 0.67 g/cm3 tapped 0.92 g/cm3

PH in water 8-9

Colour grey

Water ratio ≤1%

Water demand ≈85 %

Particle size distribution d10 ≤ 2 μm (laser granulometer)

d50 ≤ 5 μm

d90 ≤ 10 μm

Chemical composition (approximate)

Tab 1 Chemical composition of Microsphere-1250/%

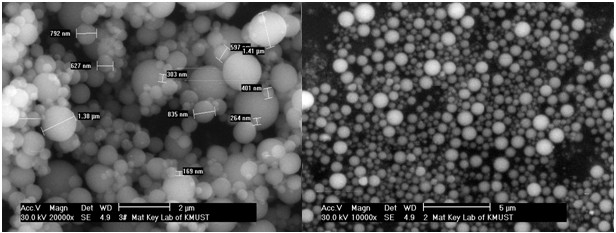

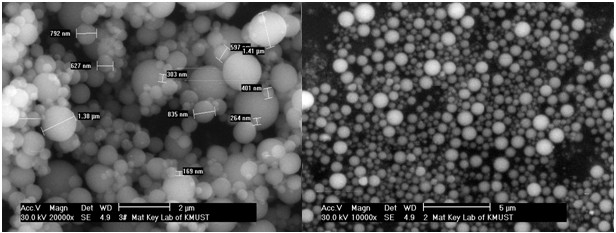

Scanning Electron Microscope (Fig 1)

The SEM of Microsphere-1250(×20000) The SEM of Microsphere-1250(×10000)

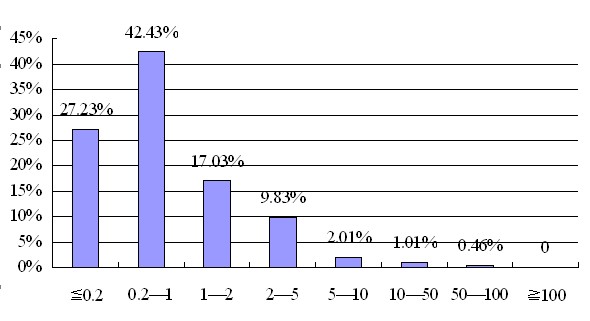

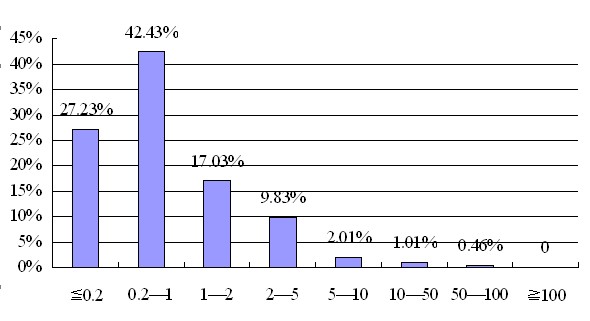

Particle Size Distribution

Fig 2 Particle size/mm

Other than using suitable cement and aggregate to prepare high performance concrete, it is necessary to add the ultrafine powder filler and efficient flow agent of low water gel ratio. The common ultrafine powder filler is silica fume, silica fume can significantly improve the strength of concrete and structural compaction, but increase water demand, reduces the workability of concrete.

At the same time, because the silica fume has better activity and higher hydration heat, concrete reaches early strength very fast, also increase the difficulty of conservation. The drying shrinkage of concrete can cause micro fractures in the late stage, all of which are the reasons of the decline in the strength, durability and other performance indicators of concrete.

Ordinary fly ash can effectively improve the fluidity and compactness of the concrete. However, due to low activity of the fly ash, it generally will not exceed the 28-day strength of cement (more dosage, more loss). The overall contribution of ordinary fly ash is limited in concrete,the effect is usually not as good as silica fume.

Microsphere-1250 provides a brand new option in the preparation of high-performance concrete It has the advantages of micro-aggregate of silica fume, It also has a better physical water-reducing effect and high activity. It can reduce the water demand and the hydration heat in the preparation of high performance concrete, and improve the density of concrete. The application characteristics of Microsphere-1250 in concrete as follow.

Microsphere-1250 is a global shape particle which almost doesn’t contain porous substance and the particle size is very fine which bring excellent filling and ball lubrication effect for concrete, and its physical water-reducing effect is remarkable. Under the conditions of the same slump, the water demand of concrete significantly reduces; besides, the flowing ability increases, and the water-reducing rate is about 15%.

Microsphere-1250 has a continuous and uniform particle size distribution between 0.1μm to 5μm, which makes the concrete gradation optimized excellent at the micro level. Therefore, the Concrete becomes much denser, the strength becomes higher, the impermeability and corrosion resistance are greatly improved as well. Microsphere-1250 is an optimization agent for concrete gradation.

Microsphere-1250, as a kind of aluminosilicate material with ultra fine particle, almost doesn’t react with the alkaline substances of concrete in the early stage of hydration reaction, although the average particle size of Microsphere-1250 is only 1.5μm. The strength of concrete is mainly improved by beads filling effect. Therefore, compared with other types of high specific surface area micro-filler (silica fume, etc), the concrete hydration heat is low and dry shrinkage is small in the early stage of hydration reaction. As the hydration reaction proceeds, the dense surface of Microsphere-1250 begin to be destroyed, the concrete becomes more denser, the strength becomes more higher.

Others:

Excellent rheology and workability; Excellent thixotropy; With features of reducing viscosity and the shear stress; The excellent performance of molding greatly reduce the commercial concrete slump loss in the long road transportation.

Higher activity coefficient, the activity coefficient of 28 days is 105% -110%, 56 days up to115% -120% (addition levels are 6% -24%).

Physical characteristics (approximate)

LOI 2 % (EN 196, part 2)

Particle shape spherical

Specific density 2.53 g/cm³ (EN 196, part 6)

Apparent density loose 0.67 g/cm3 tapped 0.92 g/cm3

PH in water 8-9

Colour grey

Water ratio ≤1%

Water demand ≈85 %

Particle size distribution d10 ≤ 2 μm (laser granulometer)

d50 ≤ 5 μm

d90 ≤ 10 μm

Chemical composition (approximate)

Tab 1 Chemical composition of Microsphere-1250/%

| Chemical composition (%) | SiO2 | CaO | MgO | Al2O3 | Fe2O3 | Na2O | K2O | SO3 | Carbon content |

| Microsphere-1250 | 56.5 | 4.8 | 1.3 | 26.5 | 5.3 | 1.4 | 3.28 | 0.65 | <1 |

The SEM of Microsphere-1250(×20000) The SEM of Microsphere-1250(×10000)

Particle Size Distribution

Fig 2 Particle size/mm

Other than using suitable cement and aggregate to prepare high performance concrete, it is necessary to add the ultrafine powder filler and efficient flow agent of low water gel ratio. The common ultrafine powder filler is silica fume, silica fume can significantly improve the strength of concrete and structural compaction, but increase water demand, reduces the workability of concrete.

At the same time, because the silica fume has better activity and higher hydration heat, concrete reaches early strength very fast, also increase the difficulty of conservation. The drying shrinkage of concrete can cause micro fractures in the late stage, all of which are the reasons of the decline in the strength, durability and other performance indicators of concrete.

Ordinary fly ash can effectively improve the fluidity and compactness of the concrete. However, due to low activity of the fly ash, it generally will not exceed the 28-day strength of cement (more dosage, more loss). The overall contribution of ordinary fly ash is limited in concrete,the effect is usually not as good as silica fume.

Microsphere-1250 provides a brand new option in the preparation of high-performance concrete It has the advantages of micro-aggregate of silica fume, It also has a better physical water-reducing effect and high activity. It can reduce the water demand and the hydration heat in the preparation of high performance concrete, and improve the density of concrete. The application characteristics of Microsphere-1250 in concrete as follow.

Tab 2 Comparison of several admixtures characteristics

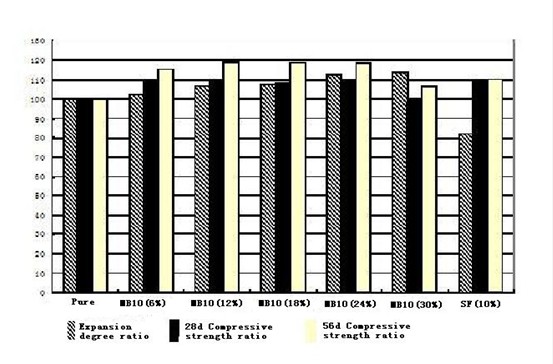

Microsphere-1250 equally replacing P·O 42.5 cement for the cement mortar experiment to compare the performance of different dosages, the dosages of Microsphere-1250 are 6%、12%、18%、24% and 30%,the silica fume is 10%.The results as follow:

| characteristics | Fly ash | slag | Microsphere-1250 | SF |

| particle size/mm | 5~30 | 10~40 | 0.1~5 | 0.1~0.5 |

| shape | Almost global shape | More edges | global shape | global shape |

| Filling ability | ordinary | bad | good | good |

| water reducing rate | good | bad | excellent | bad |

| Workability | good | good | excellent | bad |

| activity | bad | good | good | excellent |

| Anti-cracking ability | ordinary | ordinary | good | ordinary |

Microsphere-1250 equally replacing P·O 42.5 cement for the cement mortar experiment to compare the performance of different dosages, the dosages of Microsphere-1250 are 6%、12%、18%、24% and 30%,the silica fume is 10%.The results as follow:

Figure 3 shows that Microsphere-1250 is significantly superior to the silica fume in improving mortar flow, the 28-day strength is higher than the non-doped and 56-day strength is significantly higher than the cement and silica fume when the content is less than 24%, all of which show the activity coefficient of Microsphere-1250 is much larger than normal fly ash.

We believe that the quality of the Microsphere-1250 is superior to Europe Microsit M10 of quality ultrafine fly ash in accordance with the contrast of the particle size, particle shape, and the chemical composition and other indicators; Durability test shows that Microsphere-1250 has effect to improve concrete impermeability; Sulphate resisting performance test shows that the sulphate resisting performance of Microsphere-1250 is superior to general fly ash and silica fume; Frost resistance and ice-melting salt resistance performance tests show that the frost resistance and ice-melting salt resistance performance is superior to CEM I cement and more significantly superior to the ordinary fly ash and silica fume.

Application in Civil Engineering

Microsphere-1250, as a new type of concrete additives, its excellent characteristics improves aspects of the performance of concrete dramatically. The high-performance application in concrete engineering has experienced a massive increment in recent years.

Our customers also use Microsphere-1250 in constructional engineering projects, in residential buildings, in earth work and road construction as well as in many special constructions. Outstanding examples are the Skyscrapers and bridge constructions(Marine concrete) in many cities of China. Shenzhen Kingkey Finance Tower preparation C120 concrete using Microsphere-1250 can continuously pump up to 410 meters; China State Construction Engineering Corporation uses Microsphere-1250 in preparation C80 concrete with superb pumping performance; Guangdong Sanhe pipe piles uses Microsphere-1250 to produce non-autoclaved PHC pipe pile; and a lot of new special mortar, such as self-leveling mortar, injection mortar, highly liquid fill joints mortar, abrasion resistant mortar, anti-skid mortar.

Application Examples

We believe that the quality of the Microsphere-1250 is superior to Europe Microsit M10 of quality ultrafine fly ash in accordance with the contrast of the particle size, particle shape, and the chemical composition and other indicators; Durability test shows that Microsphere-1250 has effect to improve concrete impermeability; Sulphate resisting performance test shows that the sulphate resisting performance of Microsphere-1250 is superior to general fly ash and silica fume; Frost resistance and ice-melting salt resistance performance tests show that the frost resistance and ice-melting salt resistance performance is superior to CEM I cement and more significantly superior to the ordinary fly ash and silica fume.

Application in Civil Engineering

Microsphere-1250, as a new type of concrete additives, its excellent characteristics improves aspects of the performance of concrete dramatically. The high-performance application in concrete engineering has experienced a massive increment in recent years.

Our customers also use Microsphere-1250 in constructional engineering projects, in residential buildings, in earth work and road construction as well as in many special constructions. Outstanding examples are the Skyscrapers and bridge constructions(Marine concrete) in many cities of China. Shenzhen Kingkey Finance Tower preparation C120 concrete using Microsphere-1250 can continuously pump up to 410 meters; China State Construction Engineering Corporation uses Microsphere-1250 in preparation C80 concrete with superb pumping performance; Guangdong Sanhe pipe piles uses Microsphere-1250 to produce non-autoclaved PHC pipe pile; and a lot of new special mortar, such as self-leveling mortar, injection mortar, highly liquid fill joints mortar, abrasion resistant mortar, anti-skid mortar.

Application Examples

| Name | Height | City |

| 1.Shanghai Center | 632m | Shanghai |

| 2.China 117 Tower | 597m | Tianjin |

| 3.Kingkey Finance Tower | 446m | Shenzhen |

| 4.Wuhan Center Building | 438m | Wuhan |

| 5.Guangzhou East Tower Building | 530m | Guangzhou |

| 6.Hong Kong-Zhuhai-Macau Bridge(Marine concrete) | ||

| 7.Changsha Keller International City | Changsha | |

| 8.Non-autoclaved high performance pipe pile | ||

| 9.Self-eveling mortar |